NDT process optimization for aerospace components (2)

25.01.2024

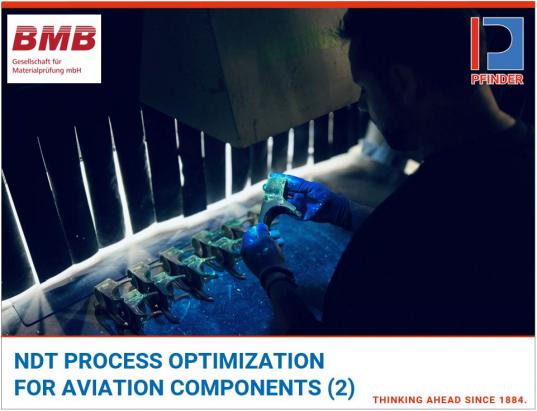

As previously announced, BMB and PFINDER are presenting a GREEN NDT project that has been implemented. The fluorescent penetrant testing of components for the aviation industry has thus become more economical, more environmentally friendly and safer for the testers. Here we present the continuation:

Before testing, all test parts for the aviation industry are dried for 10 minutes at 80 degrees. After cooling, complete wetting with PFINDER 923 takes place. The fluorescent penetrant of sensitivity class 3 is approved in accordance with AMS 2644. This is an international approval, which is particularly important for the aviation sector. Intermediate cleaning of the test parts takes place after the penetrant has been applied. Excess penetrant is removed from the surface with water. This process step produces a large amount of waste water. Depending on the penetrant used, the wastewater usually has to be disposed of as hazardous waste or treated (e.g. by activated carbon filtration, ultrafiltration or vacuum distillation). All this generates high running costs.

The composition of the PFINDER 923 penetrant is based on raw materials that lead to a recognized very good biodegradability according to EN ISO 9888. This environmentally friendly and biodegradable basis of PFINDER 923 allows the wastewater to be discharged into the sewage system, subject to approval by the relevant local authorities.